From Automotive to Marine: Real-World Applications of CSM / Hypalon® in Different Industries

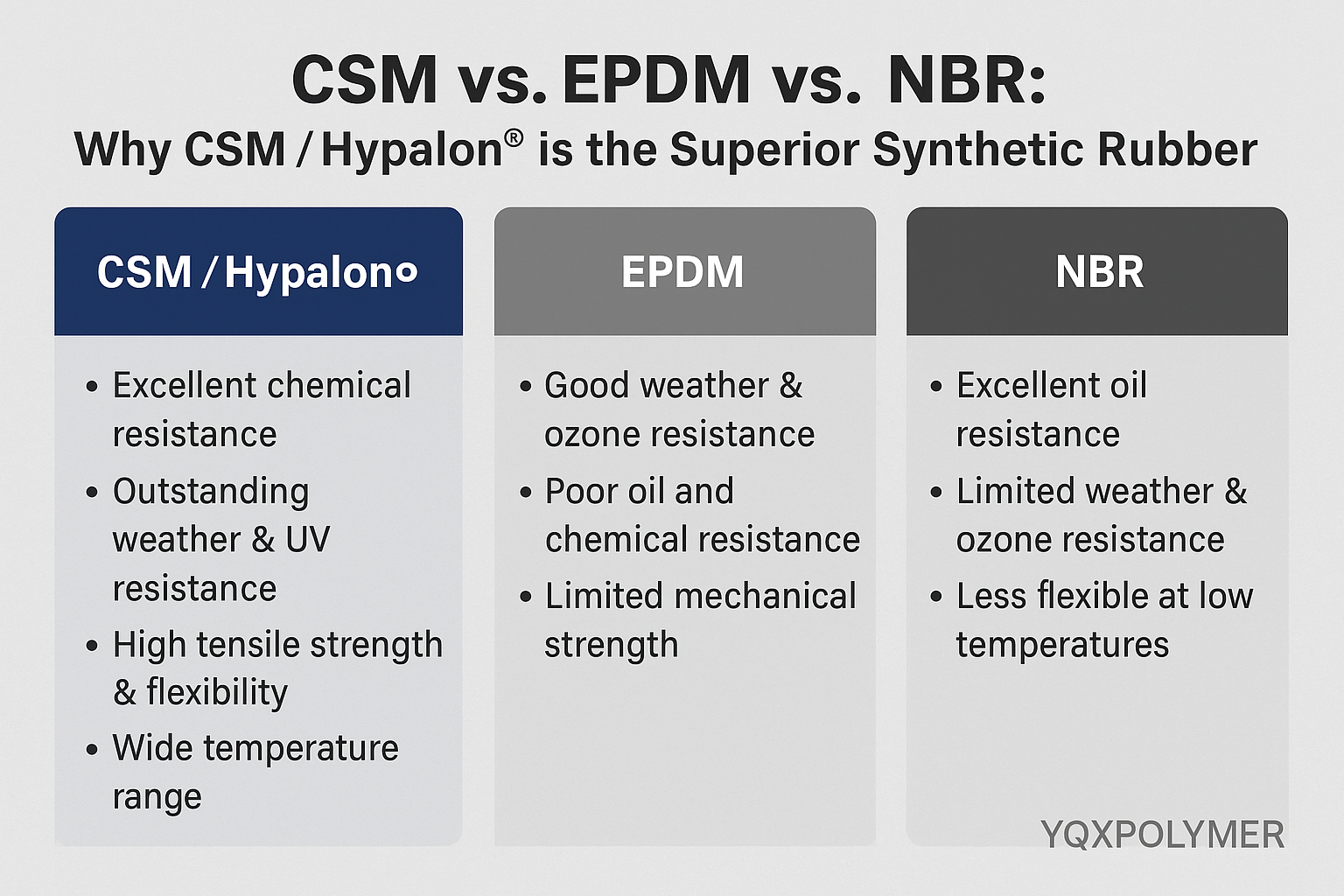

CSM (Chlorosulfonated Polyethylene), commonly known by DuPont’s trademark Hypalon®, is an exceptionally durable synthetic rubber renowned for its resistance to UV, ozone, chemicals, and extreme weather. At YQXPOLYMER, our advanced formulations of CSM rubber are trusted in demanding industries where performance under harsh conditions is non-negotiable.

This article explores real-world applications where CSM has proven to be the go-to solution for tough industrial problems.

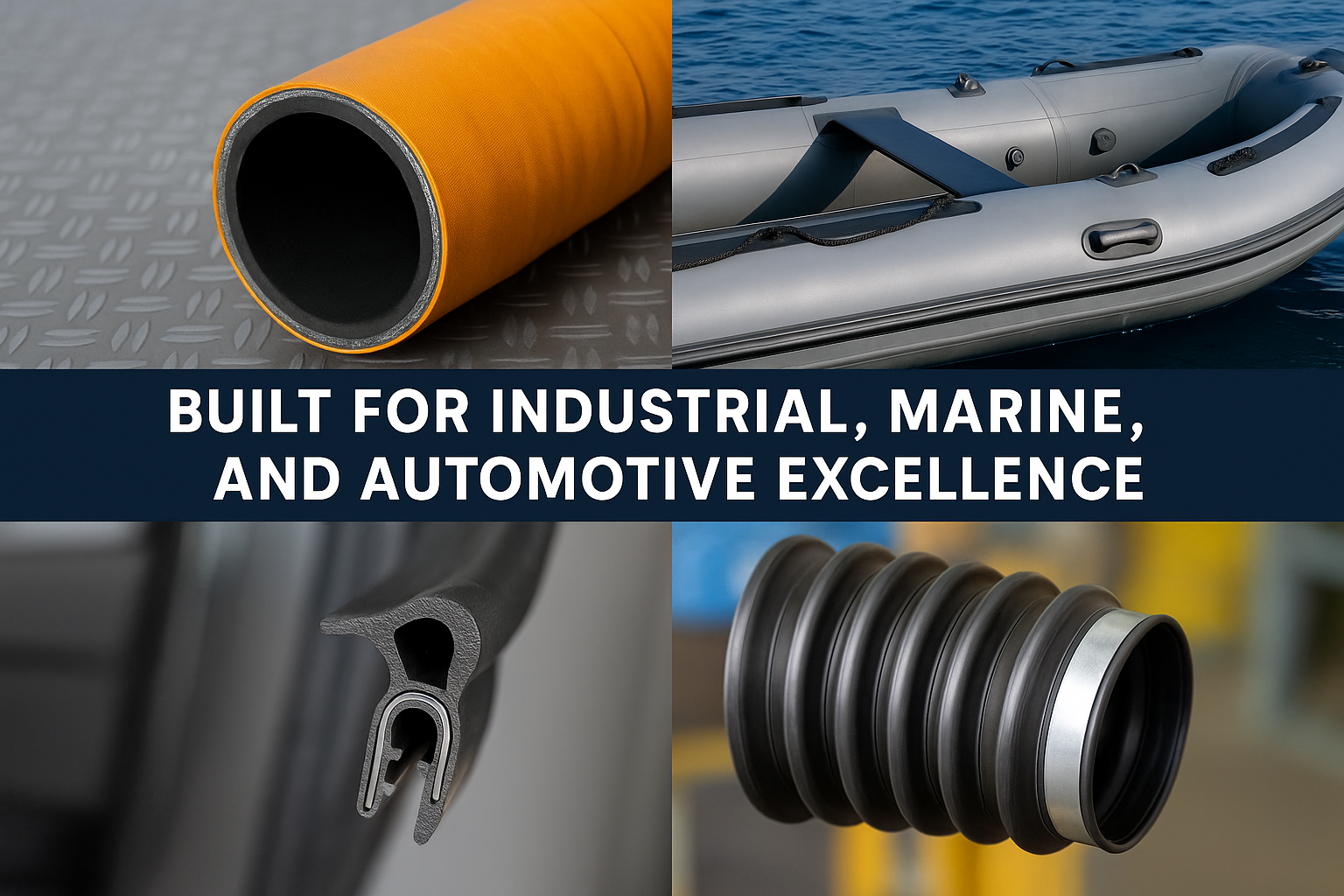

🚗 1. Automotive Industry: Durable and Heat-Resistant Rubber Parts

Problem:

Automotive components such as hoses, seals, and weatherstripping are exposed to heat, oils, and fluctuating outdoor environments.

CSM Solution:

YQXPOLYMER’s CSM rubber is used for under-the-hood hoses, battery covers, and weather seals. Its resistance to oil, coolant, and UV degradation extends the life of these components and enhances vehicle reliability.

Case Study:

A major European carmaker replaced EPDM-based battery covers with CSM rubber to increase thermal resistance in electric vehicle (EV) battery compartments, reducing premature aging by over 35%.

🌊 2. Marine Industry: Long-Term UV and Saltwater Resistance

Problem:

Boat and yacht components often degrade quickly due to sun, saltwater, and oil exposure.

CSM Solution:

CSM is the top choice for inflatable boats, fenders, and protective coatings. Its outstanding resistance to UV rays and saline environments ensures long service life.

Case Study:

A Southeast Asian boat manufacturer switched from PVC to CSM/Hypalon® for their inflatable boats. The change doubled the boats’ resistance to UV-related cracking and significantly reduced warranty claims.

🏗️ 3. Construction and Roofing: Weatherproof and Chemical-Resistant Membranes

Problem:

Roofing and waterproofing systems demand flexible materials that resist environmental exposure and aggressive chemicals.

CSM Solution:

CSM membranes offer high resistance to ozone, acids, and temperature fluctuations, making them ideal for flat roofs, chemical storage areas, and factory roofs.

Case Study:

A large chemical plant in Northern China adopted CSM-based roofing membranes to withstand acid rain and emissions. After 5 years, inspection revealed zero performance loss compared to standard TPO membranes.

🛢️ 4. Oil & Gas Industry: Resistance to Harsh Chemicals and Abrasion

Problem:

Gaskets and liners in oil & gas operations face constant exposure to hydrocarbons, acids, and mechanical wear.

CSM Solution:

CSM’s chemical resistance and abrasion tolerance make it suitable for hose linings, seals, and expansion joints used in refineries and offshore platforms.

Case Study:

An offshore drilling company replaced traditional rubber expansion joints with CSM-reinforced alternatives, resulting in a 40% increase in operational lifespan.

⚡ 5. Energy & Electrical: Insulating and Flame-Retardant Properties

Problem:

Electrical insulation materials must resist fire, arc tracking, and weathering.

CSM Solution:

CSM provides low flammability, excellent dielectric properties, and long-term outdoor durability, making it ideal for cable jackets and solar panel seals.

Case Study:

A solar farm in the Middle East adopted CSM-based gaskets for panel sealing. The material resisted UV and thermal aging in the desert climate for over 7 years without degradation.

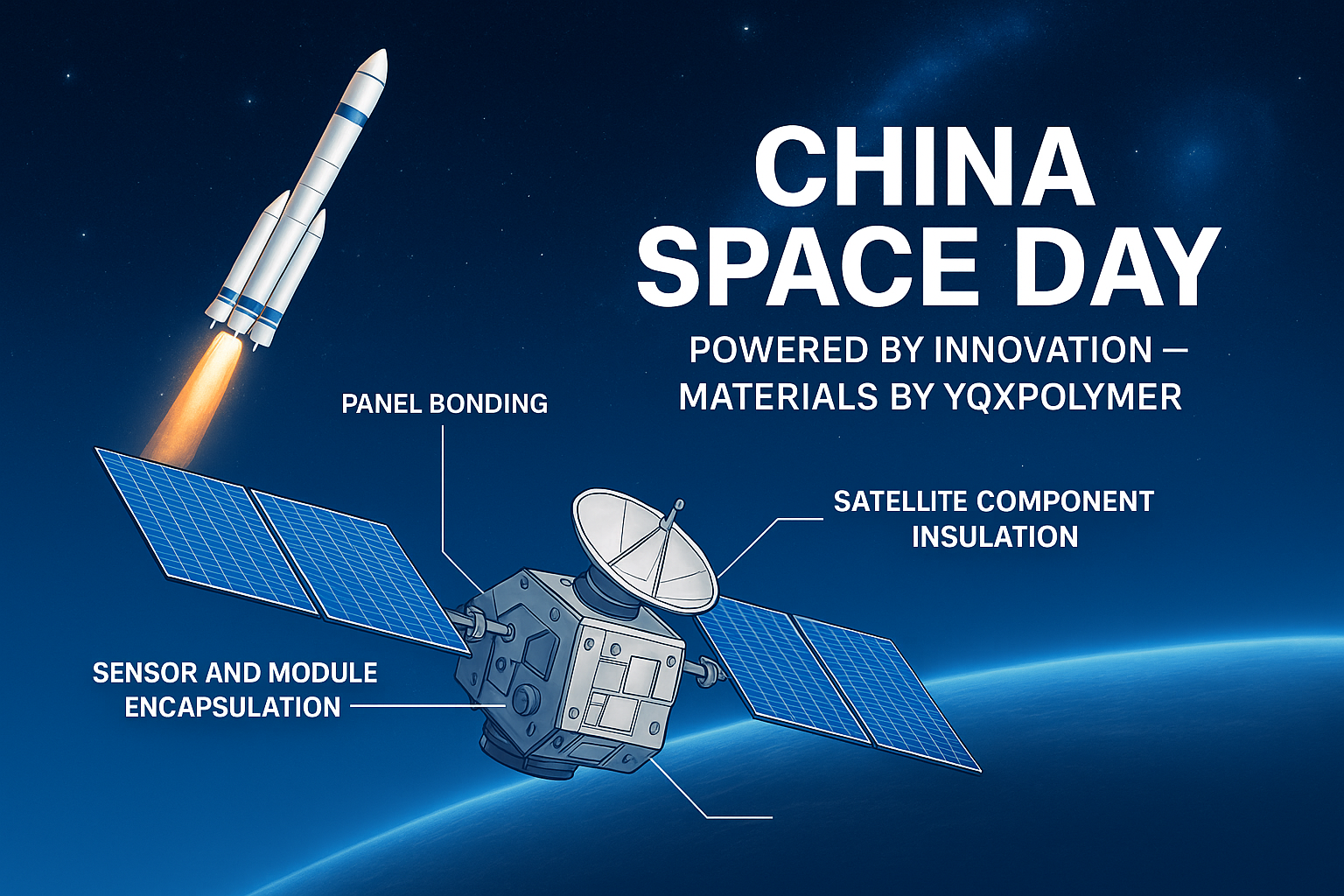

✈️ 6. Aerospace and Defense: High-Performance Under Extreme Conditions

Problem:

Aircraft and defense equipment require lightweight, flame-retardant materials that resist chemical and environmental degradation.

CSM Solution:

CSM is used in fuel system seals, flame-retardant covers, and insulation components due to its extreme durability and low smoke emission.

Case Study:

An aerospace supplier integrated CSM into protective equipment linings for helicopters, achieving FAA certification for flame resistance and improving lifecycle cost-efficiency.

Why Choose YQXPOLYMER’s CSM / Hypalon®?

- ✅ UV & Weather Resistance

- ✅ Excellent Chemical Stability

- ✅ Long Service Life in Harsh Environments

- ✅ Custom Formulations for Industry-Specific Needs

- ✅ Global Technical Support & Compliance

📞 Contact YQXPOLYMER for Custom CSM Solutions

At YQXPOLYMER, we engineer specialty CSM compounds tailored for performance-critical environments. Whether you operate in automotive, marine, or high-tech infrastructure, we can help you design a solution that lasts.

📧 Email: sales@yqxpolymer.com

🌐 Website: www.yqxpolymer.com

📞Tel: +86-28-8411-1861